Hyosung Helps Makes Denim Better with New Bio-Based, Recycled, and Recyclable Sustainable Textile Innovation

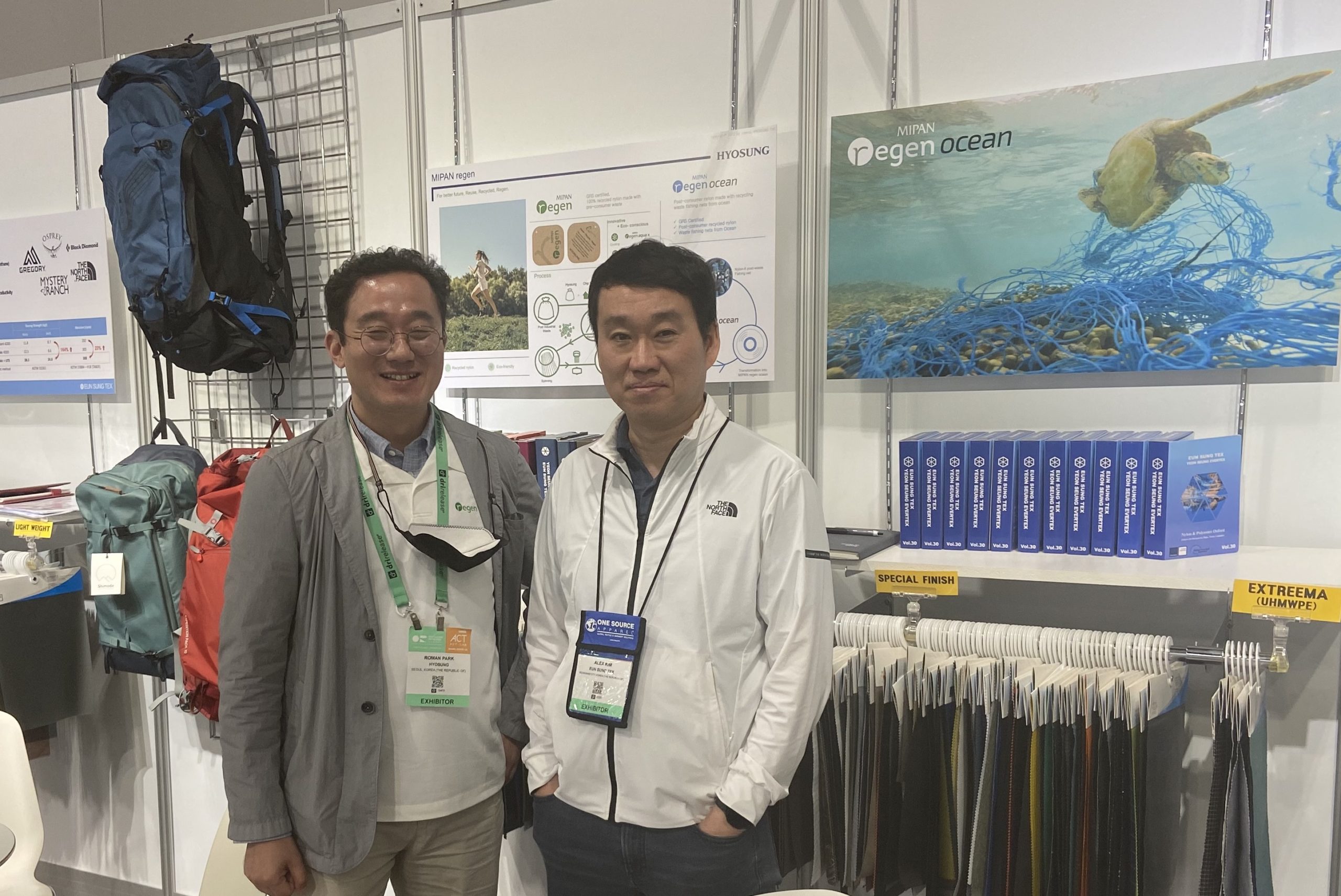

Furthering its commitment to continuous innovation and providing sustainable solutions for diverse needs across the denim value chain, Hyosung will introduce a unique offering of certified sustainable materials at Kingpins Amsterdam, October 18-19, Booth # Blue Zone 38.

According to Hyosung, sustainability is not a singular concept. Depending on a brand’s priorities for a particular product, it might recycled, bio-based, recyclable – or something else coming along on the horizon.

“While the industry is deciding which sustainable route to go, we are in a very strong position in that we can offer solutions across many of these categories, said Simon Hong, Hyosung Global Marketing Lead – Denim.

Sustainable Fibre Innovation for Denim

· creora® Bio-Based elastane – for jeans made with renewable resources

Creating a more powerful, traceable sustainable story, Hyosung is expanding its creora® Bio-Based elastane offering to include various options for the yarn to be made with a higher content of renewable resources. Hyosung was the first company to commercially introduce USDA and SGS-certified creora® Bio-Based elastane made with 30% renewable resources in 2022, which has been successfully adopted by leading global brands. According to an independent 3rd party LCA, the manufacture of 1kg creora® Bio-Based elastane reduces its carbon footprint by 20% as compared to the production 1kg of conventional spandex.

“We are very excited to follow the success of our creora® Bio-Based elastane with a second phase of third-party certified fibres made with a higher content of renewable resources to meet consumer demand for traceable, bio-based products,” said Hong. “Customers will now have the opportunity to select the option that meets their needs.”

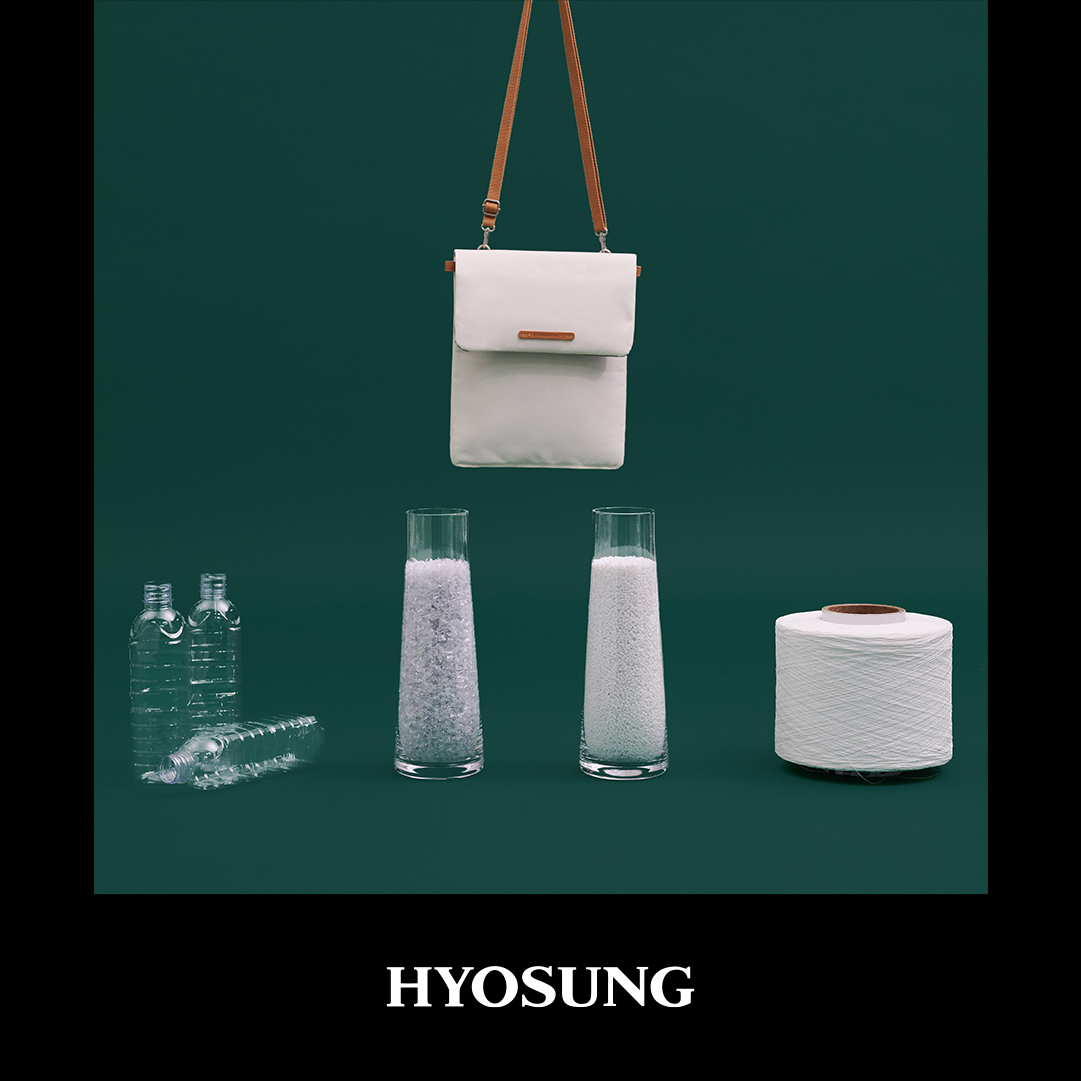

· creora® regen elastane – for jeans made with 100% recycled materials

In 2020, Hyosung introduced RCS-certified, 100 percent recycled creora® regen elastane made from reclaimed production waste. Since then, leading denim brands and retailers have adopted the fibre to offer a completely recycled product to consumers.

· creora® 3D Max spandex – for recyclable jeans

Circularity is top of mind and denim brands and mills are following Ellen MacArthur Foundation’s Jeans Redesign guidelines for recyclable denim. Among its guidelines is a requirement that denim be made with a minimum of 98 percent cellulosic material leaving 2 percent of the content for stretch or synthetic material – a challenge for Jeans Redesign participants as consumers are accustomed to high stretch and comfort. Hyosung’s creora® 3D Max elastane delivers high-performance stretch and recovery with a very small portion of elastane content uniquely allowing the garment to be recycled.

Anticipating denim brand needs, Hyosung has expanded its creora® 3D Max elastane offering to include more sustainable and functional versions of the fibre that match the same performance and recyclability benefits as conventional creora® 3D Max elastane. They include new USDA and SGS-certified creora® Bio-Based 3D Max elastane, RCS-certified, 100% recycled creora® regen 3D Max elastane made from reclaimed production waste, and creora® Easy 3D Max elastane that provides soft power with excellent stretch and recovery.

Better Together

When it comes to developing sustainable technologies and programs, partnerships can provide many benefits for the companies and brands involved.To support improved speed to market for new yarns, Hyosung works closely with its with global denim mill partners in markets such as Turkey, India, Vietnam, Pakistan, and China to develop fabrics that meet consumer needs.

At Bossa, a Hyosung long-standing mill partner based in Turkey, a successful collaboration entails having a mutual point of view on sustainability issues – with both its company and its customers.

“A fiber supplier has to be open minded for R&D activities prompted by changing denim trends,” said Mehmet Aplay, Product Development Chief, Bossa. “Socially and ecologically responsible textile production backed by valid certification systems is essential. And surely, respectable production, and on-time delivery are critical.”

According to Turkey-based Kipas, a Hyosung mill partner since 2013, innovation, sustainability, consistency in high-quality production, and value are all very important to a collaborative partnership.

“Our partnership with Hyosung permits us to offer many sustainable solutions to our brand partners,” said Ömer Faruk Aksoy, Sales and Marketing Manager, Kipas. “A request from denim brands looking to develop a product made with renewable resources prompted us to collaborate with Hyosung on its creora® Bio-Based elastane for the project, which we’ve made very good progress on.”

Both mills are of the opinion that the industry must shoulder the responsibility of environmental care. They firmly believe that a continued focus on utilizing low-impact raw materials and recycling textile waste to achieve full circularity will be crucial for the future of the textile market.

“It’s widely acknowledged that sustainability is a journey,” said Hong. “The industry and consumers possess a greater comprehension of the textile industry’s environmental footprint, and there is a strong commitment to effecting positive change. Hyosung is committed to maintaining our position as a pioneer in the advancement of sustainable textile solutions to support our value chain on this path.”