Stories | June 26, 2020

Hyosung presents Shared Developments with mill partner, Panther Denim at Kingpins24

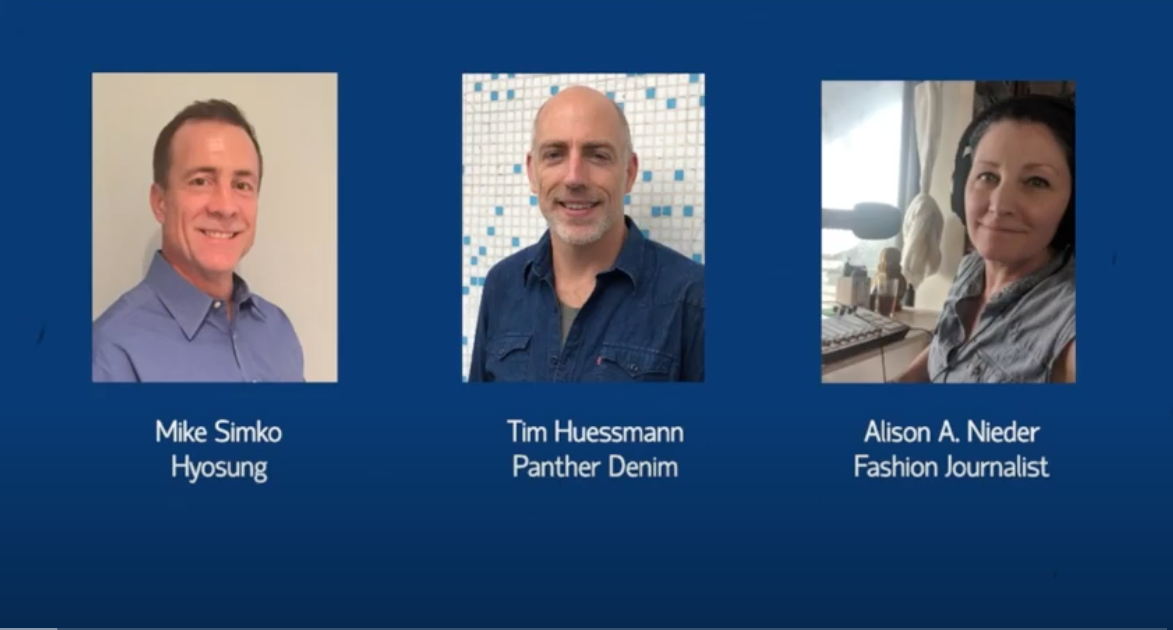

At the recent Kingpings24 event, our Global Marketing Director, Mike Simko, and Tim Huesemann with Panther Denim Tat Fung, discuss the importance of shared developments and collaboration to bring value to brands and consumers. According to Tim, we need to replace the term supply chain with value chain. A value chain approach works more closely with partners to develop innovative projects all the way through from fiber → yarn → weaving → dyeing → garment manufacture → brand, and finally to the consumer so that all will benefit. You can listen here in case you missed it, and the transcript is provided below.

Alison Nieder:

I’m fashion journalist, Alison Nieder, and I’m joined by Mike Simko, Hyosung’s Global Marketing Director for Textiles, and Tim Huesemann, Sales Director for Panther Denim. We’re going to talk about the partnership between Hyosung and Panther, and some of the new products that Hyosung has on the market, specifically for denim. Welcome, Mike and Tim.

Mike Simko:

Thank you for having us. Appreciate being part of Kingpins for the second time, second virtual time, but we’re here.

Tim Huesemann:

Welcome, Alison. Thanks for having us here.

Alison Nieder:

Let’s start off by talking more about this partnership. I don’t know which one wants to kick off with that question.

Mike Simko:

Tim, if you don’t mind, let me kick it off. So, we were seeing trends in the denim market and just so you know, at Hyosung, we do more than just denim. We have exposure to a lot of other markets, like active wear and we supply spandex, nylon, and polyester to a whole host of markets. And one thing we’ve been noticing is that the traditional market segments, we think things like hosiery, active wear, swimwear, intimate apparel, those lines are kind of blurring and we’re seeing crossover. So we’re seeing things like the intimate apparel business being interested in technologies that the active wear business use. So things like wicking and cooling. You look at office and commuting and so now, there’s a trend of crossover where you need a lot of stretch, because you ride your bicycle into work and those sorts of things. And so again, crossover. And we’ve noticed that in denim as well. So we’re looking for new functionalities in denim. And, I guess we can’t do it alone, so we decided we had to go find a good partner and we’re working with Panther to help us do that.

Alison Nieder:

Tim, can you kind of elaborate how the partnership works on your end?

Tim Huesemann:

Yeah, we are really happy and welcome Hyosung for all these innovations and developments they are providing us. And yeah, I believe that a strong and successful partnership only works in the denim industry if we actually create the first big key element, which is the value chain and not a supply chain. I think the books have to be rewritten in economics, so don’t call it supply chain, they call it a value chain, because then you actually work with partners. So you work with partners from the fiber to the yarn to the weaving and dyeing units. Then going to the garment makers and actually to the brand and then marketing it to the consumer. And we believe that our strong partnership actually has certain elements. Key elements are trust and openness, and a commitment to the project.

So, if we do an innovation, if we get approached by a new fiber, which is on the market, we first have to think how to actually integrate it, right, into our denim products. So are there dying limitations, are there weaving limitations? Are there a lot of certain processes have to be involved to really make it happen. So for this, we actually need a strong commitment by the brand. And we look for partners, instead of just suppliers. Because the supplier is kind of the old way. You have something and you supply it at a certain price at a certain lead time, but we are now looking and I think the world will change more and more into this, that the brand reaches out to us and sees something new, or we see something new, or Hyosung, which creates so much newness in the fiber technology from sustainable to functional fabrics, that they reach out to brand and to us as a mill, and then we work together. And then because the big, big part of innovation is the timelines. So, it can be as quick as four to six, eight weeks, but it can also last a year or even sometimes two years to make the denim fabric right.

Some people may not believe this, but I am still working on one project, which was taking two years and still not finished. So one part is the cost saving and cost sharing aspect. So I believe that we all need to acknowledge that we are in the value chain and that Hyosung is investing a lot in R&D to make these fiber and these new sustainable products happen. And then, we as well, take our time to use actually these fibers, and what do we have to do? We have to prove the data that the fabric still functions and it functions based on the brand’s testing data, right? There are requirements.

Some denim brands have very strict requirements. So you have to make sure that the new fiber passes the standards. So, we are really happy to have a value chain right now in certain projects and open to do more with Hyosung on these innovations.

Mike Simko:

Tim, you mentioned the brand and I can’t emphasize that enough. I’ve worked for fiber companies all my life and we have really smart people working in a lab and bring out “here, take this”. And unless you really know that you’ve got a committed and targeted brand who’s interested, the likelihood of success is going to be lost. But, if they’re willing to guide you by giving you information and consumer feedback – that’s very critical to the partnership.

Tim Huesemann:

Right, thank you.

Alison Nieder:

I wonder Mike, if you can sort of break down some of the new products that you have, and also some of the functionality behind it.

Mike Simko:

Yeah, yeah. So, we’re newbies to the denim market. So, the community knows more about denim than we do, and it is working hard on sustainability obviously. But what we believe we could do is we could bring new tools, a new toolbox to the community, so if you’re looking for certain functionalities, something like a summer denim, we could now deliver a product, such as our aqua-X, that is cool to touch, it wicks, and then it’s quick drying. So it’s the perfect product to add that comfort for summer denim. Similarly, if you look at winter weight products, we could actually make them better by adding our aerolight. So, this is a polyester based technology – a specially engineered fiber that allows insulation. It also wicks, so it keeps the skin dry. And so you get that added layer of warmth. And then also we have stretch. We’ve recently come out with our creora® 3D Max, which is a 100% spandex-based product, which is targeted at the super stretch market. So when you want greater than 50% stretch, but you can’t tolerate any growth, this is the product that you want. And what’s also important about this fiber, it’s an enabler to allow you to use certain laser finishes, where in certain super stretch today it’s difficult. I’ll let Tim explain that a little bit more, because he’s more the expert.

Tim Huesemann:

Yes, actually. I mean, you know, we often work next to our own developments. We have to work on the brand’s requirements and the key denim brands right now all move into the laser direction, right? For laser washes and reducing the wash time to maybe just a rinse wash after the laser, but still, you know, ideally it would be 100% laser friendly fabrics. So, saying this and knowing now that the 3D Max is introduced by Hyosung, we actually see a lot of benefits of it. One part is you want to make it laser friendly denim. So you have to watch out that the polyester part is reduced, right? So, and this is now a spandex based, high stretch component. So this can really benefit the laser wash inside for any denim fabric. So this is a really big benefit.

Tim Huesemann:

We are adding now, you know, laser friendly, dying matters, which with newer recipes. So, this will even enhance the 3D Max product and make it even more sustainable because it will need less energy from the laser, but still, you know, you want to reduce the polyester part. And then the next part is the market. The COVID-19 showed it, we all want comfort. If we are more in home or if you, you know, or even if you are not at home, we want to have movement. And still the high stretch denims are a key focus still with a very authentic appearance. So, we want actually both, we want the heritage denim and we want the modern comfort. So, we develop the group of everybody’s stretch and we will now see if we can move the 3D Max into this group to make it really eye-catching and strong for the market.

Alison Nieder:

Very nice. While we’re on the subject of sustainability, I’m wondering Mike, if you can talk about socially responsible denim and some of the new products you have.

Mike Simko:

So, I mean, the denim industry has done a fantastic job in addressing environmental impacts with saving water or energy and pollution, but there’s more to go. And what we think we can do from Hyosung’s perspective is contribute to the community by supplying new tools that can be used to further environmental impact in a positive way. So we’ve recently come out with two spandex products. Why is that? Well, we built a lot of work in recycled cotton, but there’s not been the spandex to go with it. So now we can complete the story basically.

Mike Simko:

So, our first product is our creora regen spandex. This is made from 100% reclaimed waste. At Hyosung, our objective is to reduce waste. That’s not necessarily just the market products. So whether it’s our spandex or nylon or polyester, it’s all 100% reclaimed waste so that we’re maximizing the positive impact. In spandex we could’ve gone with 20% because I think you can get GRS certification, or we could have gone 50% so that we could use the logo, but we felt we would do the right thing and go with 100% because we don’t know where the future’s going to be totally with sustainability. We want to give the industry alternatives. So we’ve also introduced a bio-based product. So creora bio-based spandex is made from renewable resources, basically industrial corn. So what’s really cool about this as you grow the corn and it’s pulling carbon out of the atmosphere while it’s growing, and then you could convert that corn into chemicals to make spandex. So it’s two benefits really, one is eliminating some of the carbon in the atmosphere, but the other is you’re pulling less nonrenewable, petroleum-based raw materials in the earth. So you’re not pulling out coal or oil to make chemicals. And we think that that’s a significant part.

Alison Nieder:

And I assume in terms of performance, these are performing like any other spandex.

Mike Simko:

So, actually with the bio-based product, a fiber producer will never tell you what to drop in because there are always nuances, but it is as close as I’ve ever seen to amazing. And our regen, the recycled product is you know, a couple of tweaks in the fabric and you wouldn’t notice performance differences in fabric.

Tim Huesemann:

And Alison, yeah, maybe I want to add one more part important to the audience of the denim audience. So just imagine you take, actually these creora® regen recycled spandex, and you actually add it to, let’s say a recycled cotton and a recycled lyocell like for instance, REFIBRA from Lenzing, and you actually combine all these components, make a completely recycled a story about your new denim product. This I would love. Same with the bio-based creora. This is a fantastic item. Imagine our hemp denim comes up. You add hemp denim for the sustainable aspect and you use also bio-based creora, which makes the hemp denim even a step further, right. Or you just talk about your mass core product. The easiest way is to add the step of bio-based creora, for instance, into the big lines you’re already running as a denim brand, and you already go a step forward because you reduce the petroleum-based product.

Alison Nieder:

Well, awesome. We are right up against our timeline. So I really appreciate you both coming and joining me and telling me a little bit about the new products and how your partnership works.

Mike Simko:

Great. Allison, thank you. And we look forward to people reaching out and seeing how we can help them.

Tim Huesemann:

Yes. Thanks a lot Alison. And thanks a lot to Mike for having us as a partner here. Thank you a lot.