News & Events | April 19, 2022

How Hyosung’s Value Chain Support Goes Beyond Fiber Production

Sarah Jones, a business reporter with Sourcing Journal, interviewed Mike Simko, Hyosung Global Marketing Director – Textiles, for a recent promotional article that ran in the publication. The two discuss how Hyosung’s value chain support goes beyond supply only fiber.

Sustainability and supply chain upheaval are remaking the relationships between raw material makers and their brand customers.

Traditionally, brands have largely dealt with their direct suppliers. But with escalating transparency demands, they now need to go back further and engage with their upstream vendors—including fiber producers—to ensure that their claims are true. “The whole sustainability discussion has really made it obvious that the value chain has to be more cooperative and more engaged with each other,” said Mike Simko, global marketing director for textiles at synthetic fiber producer Hyosung.

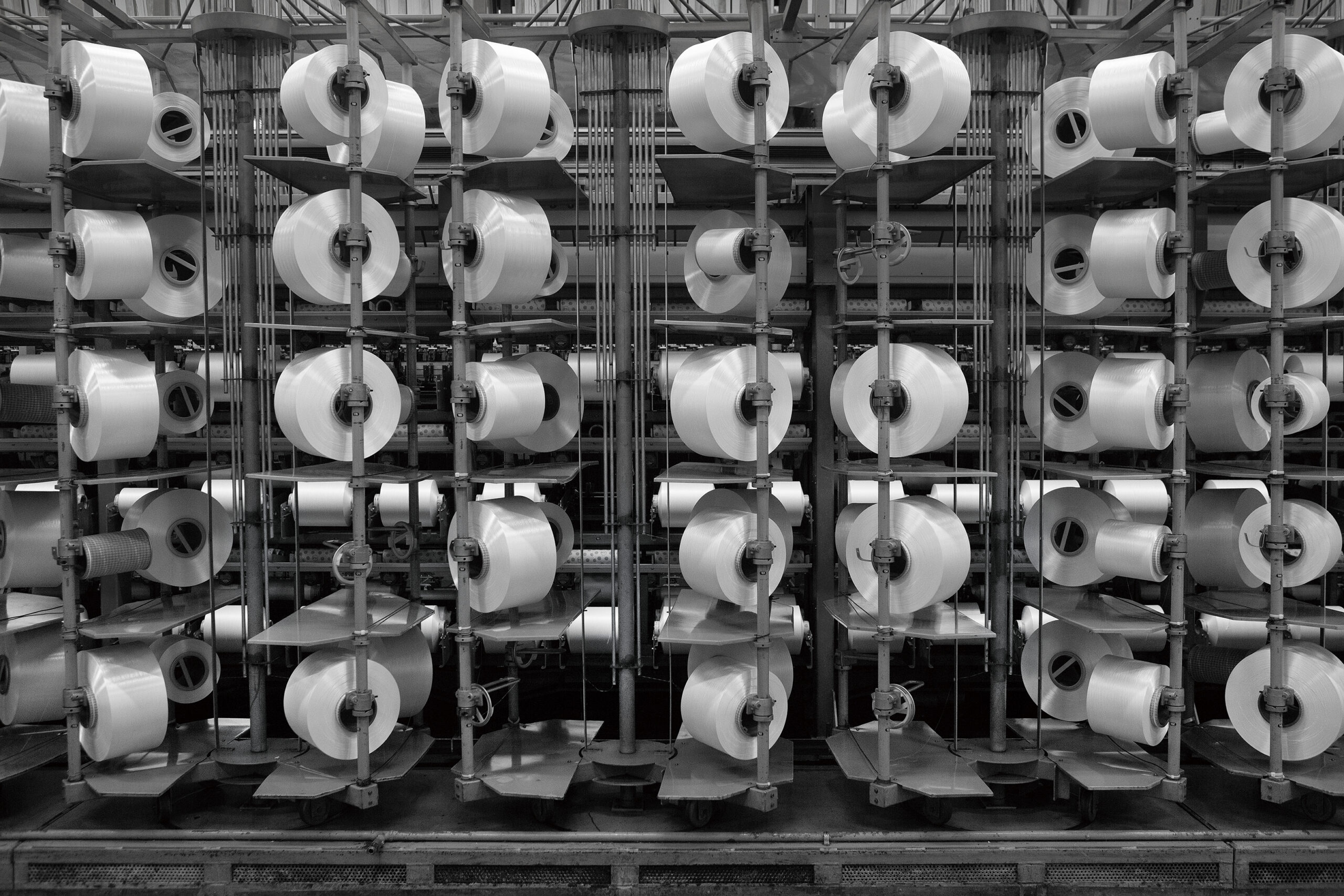

Headquartered in South Korea, Hyosung has recently been moving beyond being simply a raw material manufacturer to becoming a true sourcing and product development partner. “At the end of the day, we get paid by selling fiber,” said Simko. “But what we find is, if we’re providing that added value, then people will come seek us out.”

While sustainability originally drove this shift a little over a decade ago, more recently this ramped-up collaboration has benefited brands. “The last couple of years with the pandemic and the supply issues have really shown the power of having those relationships across the value chain,” Simko observed.

Market intel & innovation

Simko is part of Hyosung’s global brand marketing team sitting in offices across 40 countries that engage directly with brands and retailers. During the pandemic, they were able to provide advice and alternatives. For instance, when a brand’s production needed to be moved, they could suggest a mill partner in a particular location. As brands seek to narrow their supplier partners and nearshore, Hyosung has also been able to provide advice. Hyosung’s global presence not only gives it localized market intelligence, but also allows it to engage with customers across all time zones. For instance, the U.S. team might chat with a domestic brand to kick things off, and then the team in the supply country can take over the coordination. Hyosung’s worldwide presence also includes 14 production facilities, and it expanded and opened new plants mid-pandemic as demand heated up.

Hyosung has one-third of the spandex market share, and it also has all three major synthetic materials—spandex, polyester and nylon—under one umbrella. “That gives us a huge network for intelligence and finding trends and understanding issues,” said Simko. This could be anything from pricing trends in synthetics to finding the specific type of material that will fit their needs.

The company’s Fashion Design Center scopes out emerging trends, which are then shared with clients, and ultimately, the industry. To disseminate this information more creatively, the FDC is developing a virtual avatar to act as an influencer and trend reporter on Hyosung’s blog.

“We spend a good amount of time just working with our partners—whether they’re brands or retailers—helping them understand what’s going on in the industry,” said Simko. “They obviously have their own contacts and information, but we can often times help them better understand any potential issues that could be coming down the pipe.”

Hyosung has seen brands and retailers use its testing services to not only provide quality assurance, but also enable them to position products by backing up their sustainability or functional claims. “Whether it’s a sustainability story or a thermoregulation story, we want them to have data and supporting documentation to be able to communicate that to their consumers,” Simko said.

In addition to partnerships with its customers, the manufacturer also emphasizes and seeks out strong alliances with fiber producers outside the synthetic space. As Simko pointed out, spandex is always a minority blending partner—whether it’s adding stretch to cotton jeans or activewear. Considering how elastane will be used in conjunction with materials like cotton, Hyosung developed creora Color+, which can be dyed so it matches the rest of the textile fibers. This eliminates grin through, or the effect of shiny, undyed spandex fibers poking through.

Another consideration is sustainability symbiosis. For instance, it can pair its dope dyed s creora Black dope dyed polyester or cellulosic fibers. This process injects color into the fibers when they are in liquid form, ahead of spinning. This combination reduces water usage and also tells a durability story by boosting color retention.

In circularity, Hyosung is also going beyond its own manufacturing process working with Korean government municipalities to collect domestically discarded plastic bottles and fishing nets as feedstock. To close the loop, several Korean brands are adopting Hyosung’s regen jeju or regen Seoul, polyester material made from PET bottles picked up on South Korea’s Jeju Island or city of Seoul . “We are very interested in looking for alternative materials to recycle rather than having them become waste or landfill,” said Simko. A consumer’s recycled bottle might become a garment that they purchase later. “You’re helping yourself, you’re helping the environment, and it’s almost like a perfect closed loop.”